Search results

Search for "polymer coatings" in Full Text gives 17 result(s) in Beilstein Journal of Nanotechnology.

Antimicrobial and mechanical properties of functionalized textile by nanoarchitectured photoinduced Ag@polymer coating

Beilstein J. Nanotechnol. 2023, 14, 95–109, doi:10.3762/bjnano.14.11

- adhesion, etc.) [32][33]. The deposition techniques are also costly, time-consuming and restrictive (under vacuum, numerous steps, toxic chemicals, etc.), which limits industrial scale-up options. Nanometal-polymer coatings offer an interesting alternative to the aforementioned metallized textiles. Such

- functionalized side of the fabric. In order to assess the adhesion properties of the Ag@polymer coatings on the cotton fabric, scratch tests were carried out on the smooth surfaces of each type of coating, i.e., Ag@PEG600DA and Ag@PEG600DA/PETIA. In accordance with the NF EN ISO 2409 standard regarding paints

Silver nanoparticles induce the cardiomyogenic differentiation of bone marrow derived mesenchymal stem cells via telomere length extension

Beilstein J. Nanotechnol. 2021, 12, 786–797, doi:10.3762/bjnano.12.62

- aggregates [34]. Polymer coatings can be used to prevent the NPs from aggregating. In the present study, polyvinylpyrrolidone-coated Ag-NPs were used. Another important aspect of the behavior of Ag-NPs is the rate and degree of the dissolution of Ag-NPs, which depends on their surface functionalization

Surface characterization of nanoparticles using near-field light scattering

Beilstein J. Nanotechnol. 2018, 9, 1228–1238, doi:10.3762/bjnano.9.114

- moderately spherical, with an average diameter of 18 ± 2 nm (n = 20) for uncoated SPIOs, 30 ± 6 nm (n = 20) for PEG-SPIOs, and 39 ± 5 nm (n = 20) for IPC-SPIOs. There was a gradual increase in size with the addition of the polymer coatings on the SPIOs. Hydrodynamic diameter and zeta potential of

Cyclodextrin inhibits zinc corrosion by destabilizing point defect formation in the oxide layer

Beilstein J. Nanotechnol. 2018, 9, 936–944, doi:10.3762/bjnano.9.86

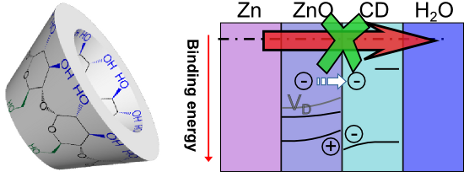

- ) compounds, and environmentally friendly alternatives are needed [2][7]. Control experiments in a recent work on encapsulating poorly water soluble organic corrosion inhibitors in the cyclic oligosaccharide β-cyclodextrin (β-CD) for incorporation into model polymer coatings on zinc led to the surprising

Bioinspired self-healing materials: lessons from nature

Beilstein J. Nanotechnol. 2018, 9, 907–935, doi:10.3762/bjnano.9.85

Vapor-based polymers: from films to nanostructures

Beilstein J. Nanotechnol. 2017, 8, 2219–2220, doi:10.3762/bjnano.8.221

- using techniques such as plasma-, initiated-, or oxidative chemical vapor deposition polymerization [4][5]. The reason for the ongoing interest in this research field is that, analogue to the deposition of inorganic coatings by chemical vapor deposition, the deposition of polymer coatings from the vapor

- phase has many advantages over traditional, wet chemistry methods. These advantages result in a variety of benefits for vapor-based polymer coatings and their broad utility. Due to the absence of solvents, dewetting effects are less pronounced, which together with the fact that small monomers instead of

A systematic study of the controlled generation of crystalline iron oxide nanoparticles on graphene using a chemical etching process

Beilstein J. Nanotechnol. 2017, 8, 2017–2025, doi:10.3762/bjnano.8.202

- quality of the transferred graphene. The protective polymer coatings typically used generate residues and contamination on the ultrathin graphene layer. In this work, we have developed a graphene transfer process which works without a coating and allows the transfer of graphene onto arbitrary substrates

Surface functionalization of 3D-printed plastics via initiated chemical vapor deposition

Beilstein J. Nanotechnol. 2017, 8, 1629–1636, doi:10.3762/bjnano.8.162

- used to deposit functional polymer coatings [21][22]. In the iCVD process, monomer and tert-butyl peroxide (TBPO) initiator are introduced in the vapor phase to a reactor chamber under vacuum, whereupon the initiator is thermally cleaved by a heated filament array. Monomer and initiator radicals adsorb

- of the iCVD process is facile layering of polymer coatings with different chemistries, which allows for tuning of surface properties. To demonstrate this feature, substrates were coated with a hydrophilic copolymer followed by a hydrophobic polymer. Substrates were printed with ABS to demonstrate the

- insulating substrates that were coated in previous iCVD reports. Both hydrophobic (PPFDA) and hydrophilic (P(HEMA-co-EGDA)) polymer coatings were deposited onto substrates made of PLA and ABS. Thermal gradients over PLA lattices were studied and shown to decrease polymer coverage on 25 mm substrates, but

Micro- and nano-surface structures based on vapor-deposited polymers

Beilstein J. Nanotechnol. 2017, 8, 1366–1374, doi:10.3762/bjnano.8.138

- have recently attracted considerable attention. The multifunctional, gradient, and/or synergistic activities of using such interfaces are also discussed. Finally, an emerging discovery of selective deposition of polymer coatings and the bottom-up patterning approach by using the selective deposition

- the resulting coatings are mostly applicable to a wide range of substrate materials [1]. In addition, the vapor deposition process typically provides excellent coating fidelity, i.e., the resulting polymer coatings are conformal with respect to micrometer- or nanometer-sized topology of the substrate

- surface. These unique characteristics are due to the absence of dewetting effects [2], which can make the coatings bridge and buckle. In contrast, dewetting is often encountered in the case of solution-based polymer coatings [3]. Vapor-deposited polymer coatings are widely discussed in interfacial

Nanotopographical control of surfaces using chemical vapor deposition processes

Beilstein J. Nanotechnol. 2017, 8, 1250–1256, doi:10.3762/bjnano.8.126

- .8.126 Abstract In recent years much work has been conducted in order to create patterned and structured polymer coatings using vapor deposition techniques – not only via post-deposition treatment, but also directly during the deposition process. Two-dimensional and three-dimensional structures can be

- : polymer coatings; polymer structures; structured coatings; vapor deposition polymerization; Review Introduction Polymer coatings have wide-spread applications, from electronics [1], to sensor systems [2] to biotechnology [3]. The ability to spatially control the surface properties in order to further

- successfully applied in order to create patterned and structured polymer coatings. Structuring both in two and three dimensions can be achieved by either using masks or taking advantage of selective deposition properties on prepatterned substrates, exploiting substrate properties such as the surface energy

Vapor deposition routes to conformal polymer thin films

Beilstein J. Nanotechnol. 2017, 8, 723–735, doi:10.3762/bjnano.8.76

- films including, but not limited to, separation processes, biomedical devices, and micro/nano electronic and energy storage devices. Micro-trenches with polymer coatings by a) solution with low substrat–interface energy, b) solution with high substrate–interface energy and c) iCVD (scale bar 2 µm). a

Phospholipid arrays on porous polymer coatings generated by micro-contact spotting

Beilstein J. Nanotechnol. 2017, 8, 715–722, doi:10.3762/bjnano.8.75

Protein corona – from molecular adsorption to physiological complexity

Beilstein J. Nanotechnol. 2015, 6, 857–873, doi:10.3762/bjnano.6.88

- surface functionalizations, such as polymer coatings, may be persistently wrapped around the NP and cannot be exchanged. We point out that this leads to a situation in which not only the chemical nature of the ligand but also its persistence on the NP surface can be decisive for the biological fate of the

- . While polymer coatings are regarded as relatively stable under such conditions, other ligands can well be replaced in equilibrium-type reactions, even under chemically less complex conditions [13]. It has been discussed before, how the formation of a protein corona can change the surface functionality

- silver NPs it was shown that their cytotoxicity is predominantly caused by the release of silver ions even when polymer coatings were applied [25][113][153]. The somewhat independent modes of action of the NP surface and the core need therefore to be considered in detail to assess the biological impact

The effect of surface charge on nonspecific uptake and cytotoxicity of CdSe/ZnS core/shell quantum dots

Beilstein J. Nanotechnol. 2015, 6, 281–292, doi:10.3762/bjnano.6.26

- ]. Various functionalization strategies have been employed in order to increase the stability of the surface ligand shell and to reduce the cytotoxicity of QDs, such as the use of cross-linked polymer coatings [10][12][13] or encapsulation in a silica shell [14][15][16]. These approaches, however, also

PVP-coated, negatively charged silver nanoparticles: A multi-center study of their physicochemical characteristics, cell culture and in vivo experiments

Beilstein J. Nanotechnol. 2014, 5, 1944–1965, doi:10.3762/bjnano.5.205

- particle interaction with the environment. The persistence of such a coating under physiological conditions emerges as an important aspect for understanding interactions between nanoparticles and biological entities in general [70]. Polymer coatings are frequently stable under such conditions but other

In vitro toxicity and bioimaging studies of gold nanorods formulations coated with biofunctional thiol-PEG molecules and Pluronic block copolymers

Beilstein J. Nanotechnol. 2014, 5, 546–553, doi:10.3762/bjnano.5.64

- PEG-SH and PEO–PPO–PEO molecules resulted in decreased cell viabilities. This may be caused by the impact of forming a thicker coating layer on the AuNRs surface [33]. Many groups have reported on the encapsulation of AuNRs with other polymer coatings to improve the biocompatibility of the rod

Porous polymer coatings as substrates for the formation of high-fidelity micropatterns by quill-like pens

Beilstein J. Nanotechnol. 2013, 4, 377–384, doi:10.3762/bjnano.4.44